-

HYNC-700 Provide

easy and simplified motion control for sophisticated

injection molding Robot Automation using color touch

screen , servo Jog button, and play back step by

step motion control. New concept Robot control

technology will allow easy plant automation and

minimize your set up time and thus maximize your

profit. NEXIA, HYBRID Series

robot will be used with this controller.

ü

Powerful hand held control pendant with full color touch

screen.

Basic Features

-

Developed specially for the molding industry by

automation engineer with years of experience in the

filed.

-

Programming required no special skill or knowledge with

4 Basic Take out Step.

-

Expandable up to 80 Step with Add position & Motion,

User output and User input.

-

Mold

Program can be saved up to 99 with 80 Step Program.

-

Mold take our Routine are made by teaching the robot via

easy menu driven programming.

-

Complex task like parts stacking, palletized insert

loading and post process operation are easily

accomplished by entering the basic data for the task.

-

Input, output and logic circuits allow easy integration

with other equipment.

-

Languages:

English, Spanish and Korean

-

Input /

output signal display with LED style icon in Touch

Screen for easy maintenance. ( In Auto, Manual, Step

Screen )

-

Minimal floor space required, stand for control pendant

may be replaced with beam mounted switches and hanger.

-

Conveyor or secondary equipment start signal.

-

Defective product rejecting circuit.

|

Main

Screen |

Manual

Screen |

Automatic Screen |

|

|

|

|

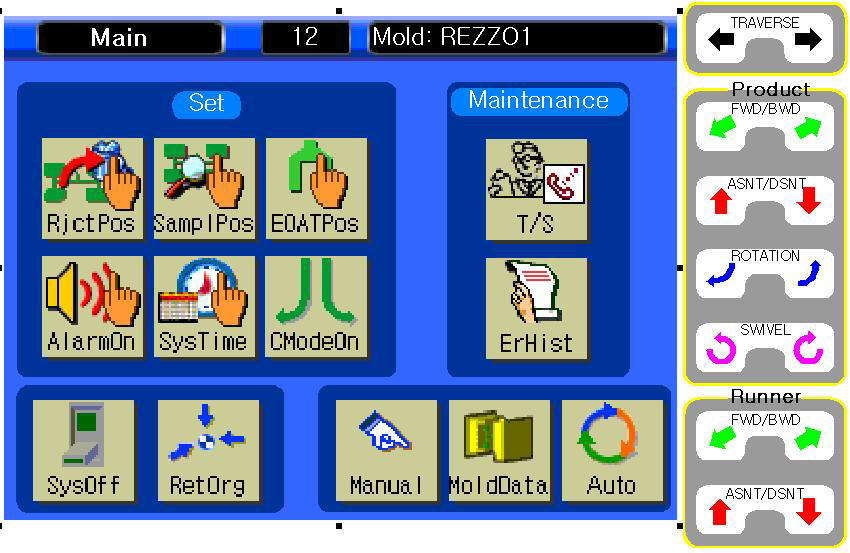

Main Screen

-

Simple Main Screen allow operator easy to

navigate all screen to access.

-

Right top corner displays current open mold

file.

-

Login Access function to allow qualified

person allow to change mold file setting.

-

Simple one Homing screen for clearing all

the mixed signal to clear with machine

interface and user output.

-

J

motion selection on / off for certain mold

file.

-

System turn off key to make sure to follow

up procedure of step.

|

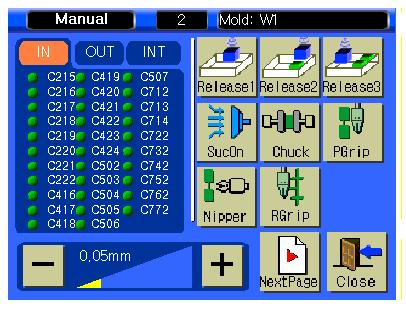

Manual Screen.

-

Manual Operation with built in Safety with

machine interface

-

Adjustable speed controls

in manual mode.

-

Actual

Position displays in screen.

-

Vacuum or Gripper circuit Valve

operation.

-

User

Output Operation to generate 24 Volt DC.

-

Soft

Membrane button switch out side of touch

screen for operation of each servo axis and

chuck rotation.

-

Input /

output / Machine Interface signal display with LED style icon in Touch

Screen for easy maintenance.

-

When robot arm goes in to molding area in manual

mode, Robot doesn't allow mold close for built in

safety.

|

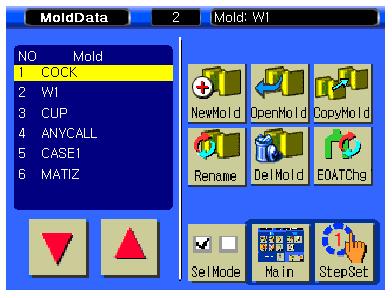

Mold File Screen.

-

Creating new mold with one touch button.

-

Open

exisiting saved mold to recalll mold file.

-

Copy

exisiting mold file with different name with

pattern of motion ( without position ) or

all data including position.

-

Rename mold file with different name.

-

Delete mold file when mold project is not

available.

-

Back

up file inside of robot controller

-

Restore file from inside of robot controller

which backed up in the past.

-

Back

up to Laptor ( USB stick ) with RS-232

connection.

-

Saved or selected Mold selection allow robot

control variout function depends on each

mold

-

Step

set allow check mold file is right position

for each step.

|

| |

|

|

|

Step Set

Screen |

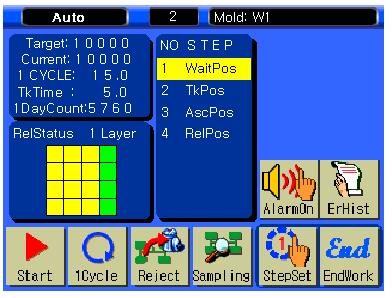

Automatic Screen

|

Palletizing Screen |

|

|

|

|

Step Set

Screen

-

Programmable for any molding automation with easy

step add function with 4 Basic Safety Position

-

Basic parts take out step is only 4 line. (

4 Step )

-

Add

Position and Motion can be added up to 80 steps to

easy to set up gate cutting or others.

-

Simultaneous and coordinated motion control for each

Axis can be selected.

-

Add User

Output to communicate with 2ndary automation, Wait

User input to receive signal from 2ndary automation

for Insert Molding, IML automation.

-

Servo Jog

Button for 1 Step motion to make sure position is

accurate.

-

Touch Jog

button or 1 Step

Forward or 1 Cycle Slow.

-

Special Designed Insert Picking Step for

Insert Molding Application.

|

Automatic Screen

-

Start and Stop for Auto Production with

automatic interface with Molding machine

-

Dry

1 cycle to allow only machine to run in 1

Cycle without machine operation yet still

checking interface safety.

-

Auto

Button will start with molding machine

automatically.

-

Reset

Total Production Counter, Goal and Current will

blink on robot beam.

-

1 Cycle

Fast Operation, Pause and Restart in Auto.

-

Adjustable speed controls in auto ( while robot is

in operation ).

-

Adjustable

Position controls in auto ( while robot is

in operation ).

-

Rejected

Signal will separate parts to desired position. (

Either from molding machine or 2ndary automation )

-

Palletizing screen to check current status

stacking.

|

Palletizing Screen

-

In

Release step, built in palletizing screen

allow operator to use stacking.

-

From

release position, up to 99 different

position for each axis with distance.

-

Built is safety of stroke to program check

palletizing safety not allow robot to be out

of range of operation.

-

Main

Position is for different position stacking

for each cycle.

-

Sub

Position is for multi cavity release positon

for 1 cycle ( Specially designed for

automotive industry for 2 cavity separation

)

-

Operator's simple input allow realize

complete stacking function.

-

Built in stacking signal allow communicate

2ndary automation like conveyor or stacking

machine.

|

| |

|

|

|

PC

Connection wtih RS-232

|

Free

Software for PC Connect |

|

|

|

|

|

|

Mold

File Management screen has TP->PC ( Upload Mold

file to Laptop )

-

Connect Laptop with RS-232 with USB Cable .

( Connect power to Laptop : 110 Volts Power

to laptop required )

-

Turn

on Power and Open File Manager program (

HYRobotics )

-

Select Port which connected USB ( Example :

COM3. COM 4 , COM 5 ).

-

Windows 7. Auto detect , Windows XP might

require special driver to convert USB to

RS-232

-

Once

connected successfully , Select Mold file

with Up/Down Arrow cursor , Press TP->PC to

Upload file to Laptop.

-

Once

upload successfully, automatically save

screen will pop up in laptop to select store

location.

Select

Store location and Save mold file for future

use. |

PC

Connect Software ( Free to Down load )

-

Connect Laptop with RS-232 with USB Cable .

( Connect power to Laptop : Power required )

-

Turn

on Power and Open File Manager program (

HYRobotics )

-

Select Port which connected USB ( Example :

COM3. COM 4 ).

-

Windows 7. Auto detect , Windows XP might

require special driver to convert USB to

RS-232

-

Once

connected , Touch : Red Icon : Data Down

Load ( PC->Touch Panel )

-

It

will open screen to select file. ( It will

require same Robot with same robot

controller version for safety. , Mold can’t

be modified from laptop.

Once

download successfully, automatically mold file

will be added in next line with name with

different number.

|

|

| |

|

|

|

|

|

|

|